Steel space frames provide great freedom of expression and composition as well as the possibility to evenly distribute loads along each rod and external constraints.

With these features, steel space frames can be used to achieve also complex geometries with a structural weight lower than any other solution. The inner highly hyper-static system provides an increased resistance to damages caused by fire, explosions, shocks and earthquakes.

Space frames are modular and made of highly industrialized elements designed with a remarkable dimensional accuracy and precise surface finish.

Transportation is particularly easy as individual frames come in small size and are easy to package. Moreover, mounting can be easily and rapidly made by not-overqualified teams.

Steel space frames can be used for the covering of both small rooms and stadiums, but also for a gas station or a church. Steel space frames are used for the covering of swimming pools, gyms, shopping malls, as well as to make up protective roofs, industrial warehouses and exposition buildings.

tetrasteel ®is specialized in turnkey design and manufacturing of steel space frames and small- and large-size lights, using its own spherical nodes systems.

Fabrication and distribution are entrusted to authorized dealers widely spread in various world markets.

PRADELLI S.R.L. metalwork factory, based in Modena, Viale Nicola Fabrizi 119, is the only authorized dealer in Italy.

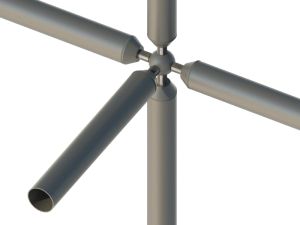

The tetrasteel Construction System® for building steel space frames

The tetrasteel Construction System®is a technologically advanced software package of calculation and graphic representation programs enabling to get all construction and assembly elements from a project plan.

STRUCTURE IMPLEMENTATION PHASES ARE:

-

- Input:

1. Steel space frame geometry modeling

2. Load applications and related combinations - Process:

1. Individual frame stress calculation

2. Selection of rod sections and sphere dimensions, with reduction of interferences and use of a continuously updatable dataset - Output:

1. 3D structure design on .dwg and .dxf files

2. Project rendering

3. Assembly designs of steel space frames

4. Structure calculation report pursuant to applicable laws in each country

5. List of required components for structure construction

6. Cutting list and manufacturing BOM for steel tubes

7. CAM file for steel spherical node drilling - Component Building:

1. Forging of spherical nodes and cones for steel space frames

2. Manufacturing of bolts and nuts

3. Manufacturing of steel space frame rods

4. Drilling of steel spherical nodes through a 5 degrees of freedom machining center

- Input:

- Surface Treatments:

1. Cataphoresis treatment

2. Powder coating and heating in furnace - Transport

- Assembly