Rods are made by S235/ S355 steel tubes of circular section; standard diameters range from a minimum size of 48mm (1.89in) to a maximum size of 324mm (12.76in), with a variable thicknesses based on the structural element specific need.

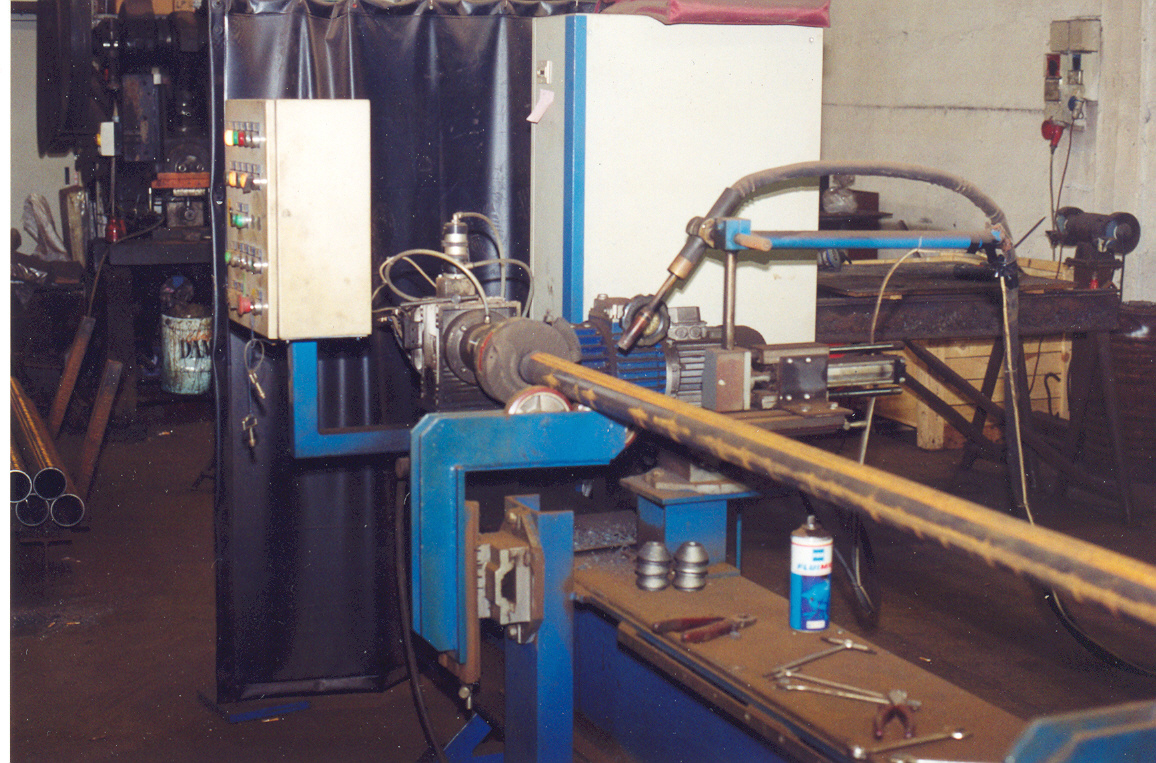

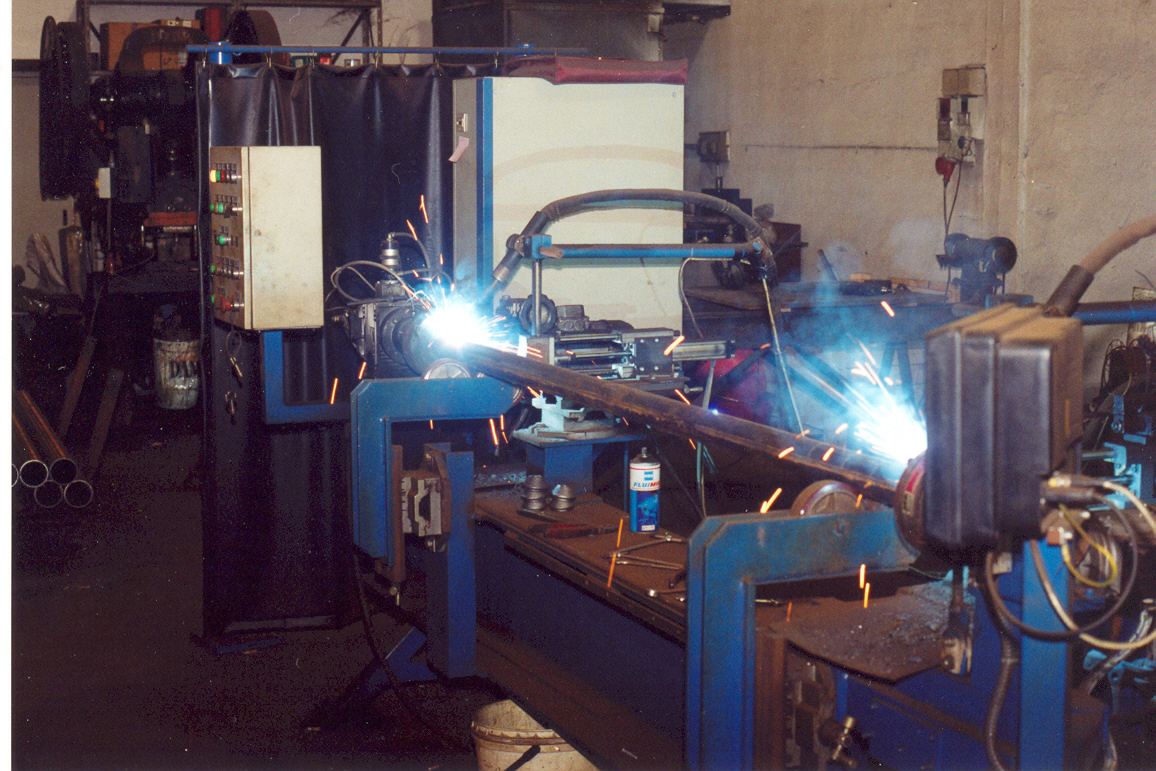

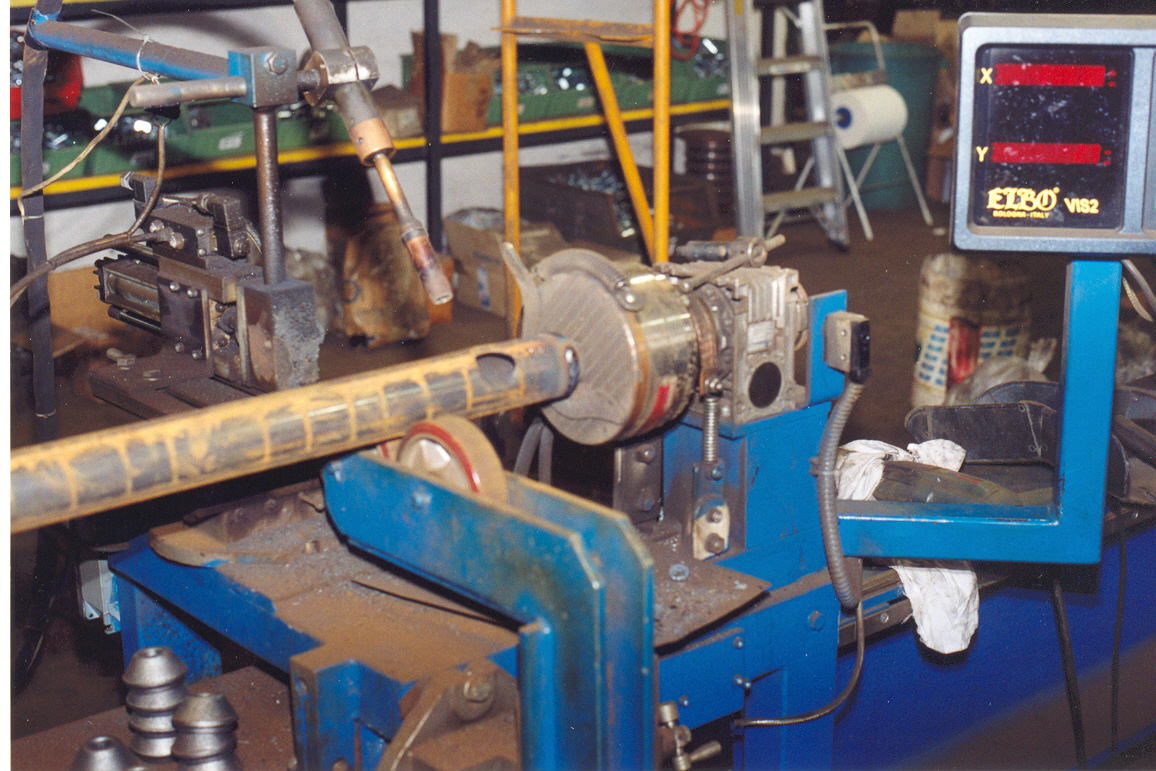

Cones are welded to the rod ends. Welding is performed by an especially designed machinery. It has a specific housing for proper cone positioning, the welding torch is fixed and turns the tube until welding is completed.